On request

Equipment warranty 12 months

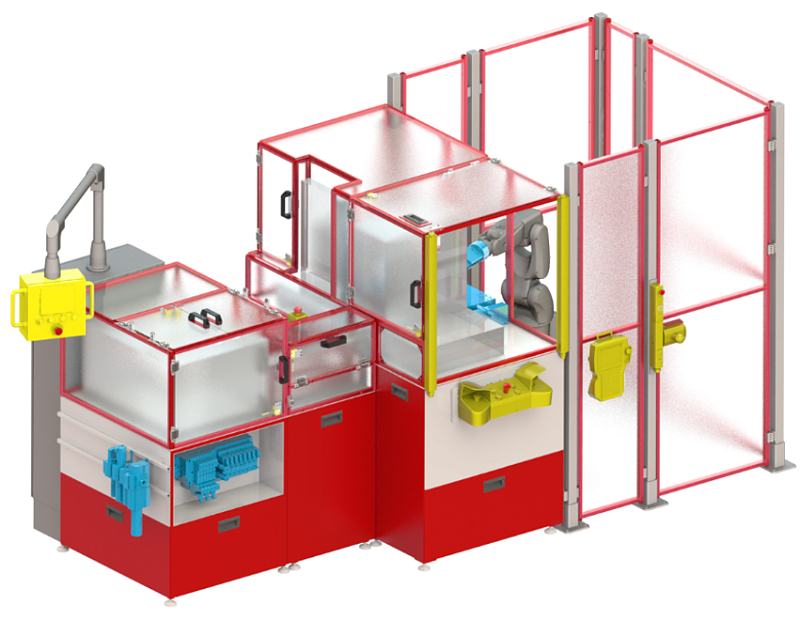

In addition to standard manipulators, RMK develops and manufactures non-standard solutions taking into account individual production requirements of the technological process.

3S guards and enclosures are integrated into the machine design to provide the required level of safety when the operator is in direct contact with the machine.

The guards and enclosures are individually designed to suit the layout of the equipment and are manufactured taking into account the local hazards: moving mechanisms, high or low temperatures, flying chips or sparks, noise, vibration, etc.

Access doors with suitable opening kinematics are provided at the operator's access points to the equipment work area and can be equipped with pneumatic, electromechanical or mechanical opening actuators as required.

Applicable standards

- GOST R ISO 12100-2010 (EN 14121) Safety of machinery. Basic principles of design. Risk assessment and reduction.

- DIN EN ISO 14120-2016 Safety of machinery. Protective devices. General requirements for the design and construction of fixed and removable guards.

- GOST R EN 953-2014 (EN 953) Safety of machinery. Protective devices. General requirements for the design and manufacture of fixed and movable devices.

- GOST 12.2.062-81 System of industrial safety standards. Production equipment. Protective barriers

- GOST R ISO 14122-3-2009 (ISO 14122) Safety of machinery. Stationary means of access to machinery. Ladders and handrails

- GOST R ISO 13857-2012 (ISO 13857) Safety of machinery. Safety distances for protection of upper and lower limbs against falling into the danger zone.

- GOST R 51334-99 (EN 294/ISO 13852) Safety of machinery. Safety distances for protection of upper limbs from falling into the danger zone

- GOST 12.2.072-98 (ISO 10218) Industrial robots. Robotic technological complexes. Safety requirements and methods of testing

- GOST R ISO 13855-2006 (EN 999) Safety requirements and test methods.